As third-pedal enthusiasts are bombarded with talk of electric cars, autonomously driving cars and eliminating gasoline and diesel engines, the future can seem bleak. But as we showed with our recent blog on the Jeep Magneto 2.0 Electric Wrangler the move to alternative propulsion for vehicles doesn’t mean the end of shifting your own gears. And here’s another example that doesn’t run on gasoline or diesel but does have a TREMEC TKX 5-speed transmission – this one makes its horsepower by burning hydrogen.

Mike Copeland and his team at Arrington Performance enjoy building vehicles that involve thinking outside of the box. Mike has been at this for a while, formerly being the brains behind building some of Chevrolet Performance’s most notable and unique custom vehicles like the Reggie Jackson Camaro and the revamp of the Project X 1957 Chevy. Believing there was still life left in the internal combustion engine (ICE), Arrington Performance set out to build a 1948 Chevrolet 3100 truck powered by hydrogen. No, not a hydrogen fuel cell generating power but an ICE running on gaseous hydrogen.

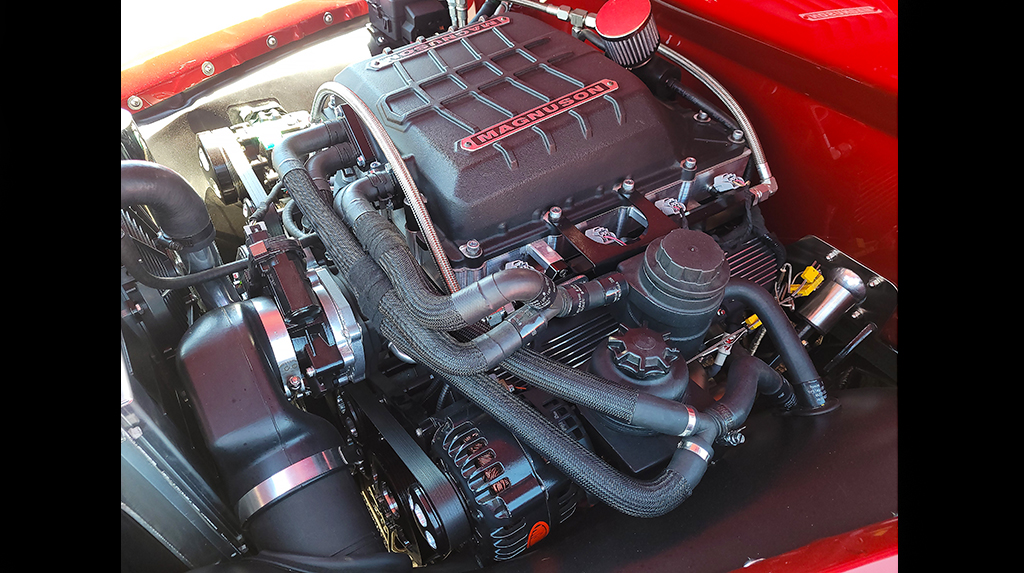

Mike explains that hydrogen is one of the most viable alternative fuel sources not just because it is plentiful, but also because of the ease of which it can be adapted to current internal combustion engine design. This simplifies conversion and reduces costs compared to other alternative propulsion systems. An interesting part of the V8 running on hydrogen is that there is no carbon burn and no carbon waste to pollute the engine’s oil as with a gasoline- or diesel-powered engine.

The engine’s temperature can even be modulated somewhat via changing the air/fuel mixture, but in normal operation the LS3 operates at 180-degrees F. The only tailpipe emission is water vapor, so the hydrogen fuel engine doesn’t require any sort of emissions system.

The engine’s ECU along with its injectors and other fuel system components come from Bosch, who Arrington Performance has partnered with to develop the system with an eye towards offering an aftermarket hydrogen fuel conversion package that can be used to keep fossil-fueled classic cars and trucks on the road if/when gasoline and diesel fuel are phased out. The Bosch ECU is plugged into an Arrington-built wiring harness, and it provides the programming and tuning flexibility necessary for the alternative fuel system to function.

Behind the hydrogen-fueled LS3 is an American Powertrain supplied TREMEC TKX 5-speed transmission supplied by American Powertrain. It uses a McCleod single disc clutch. The slimmer profile of the TKX allows for it to fit the truck’s stock transmission tunnel without modifications.

“If you didn’t know the engine as running on hydrogen, you would never be able to tell,” explains Mike. “It sounds and acts just like a gasoline engine, with no detrimental effect on the driving experience. The TREMEC TKX 5-speed and being able to shift gears manually only adds to the fun of driving the truck.”

Mike’s future plans call for racing the truck in the 2022 Optima Challenge once higher capacity injectors are available, allowing Mike to pursue his goal of making 600 horsepower with the engine.