This article is to help customers identify the cause of various driveline vibrations and guide them to finding solutions. This month, we are looking at the clutch system and the various possible causes of vibration, how to identify the source and how to remedy it.

Upgrading the transmission in a vehicle often includes changing other related components. The driveshaft angle may change (see our tech article on driveshaft vibration by clicking here). And you will most likely replace the clutch assembly, which is the most important link between the engine and the trans itself.

One of the most common issues that may arise with driveline modifications is excessive vibrations from the clutch assembly. To help clear the air about clutch vibrations we contacted the clutch experts at EXEDY Globalparts Corporation.

The first step is correctly identifying where the vibration is coming from. Evan Cline, Exedy Technical Coordinator, explained that if you feel vibrations in the vehicle at idle, deceleration or cruising with your foot off the clutch pedal, you’re experiencing the harmonic vibrations coming from the engine or driveline.

The engine will generate rotating and combustion frequencies. The majority of these frequencies are caused from the firing pulses in the cylinder.

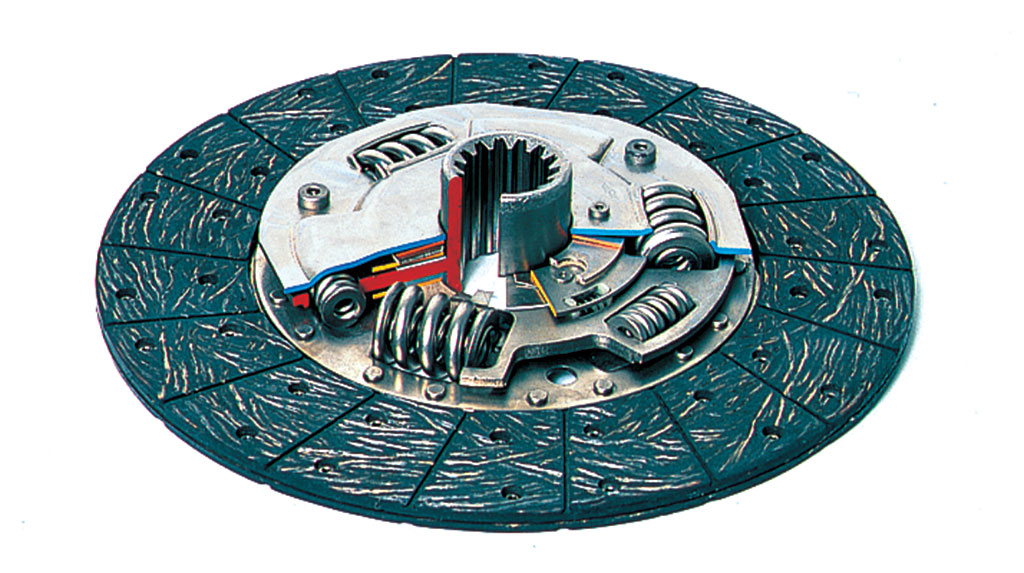

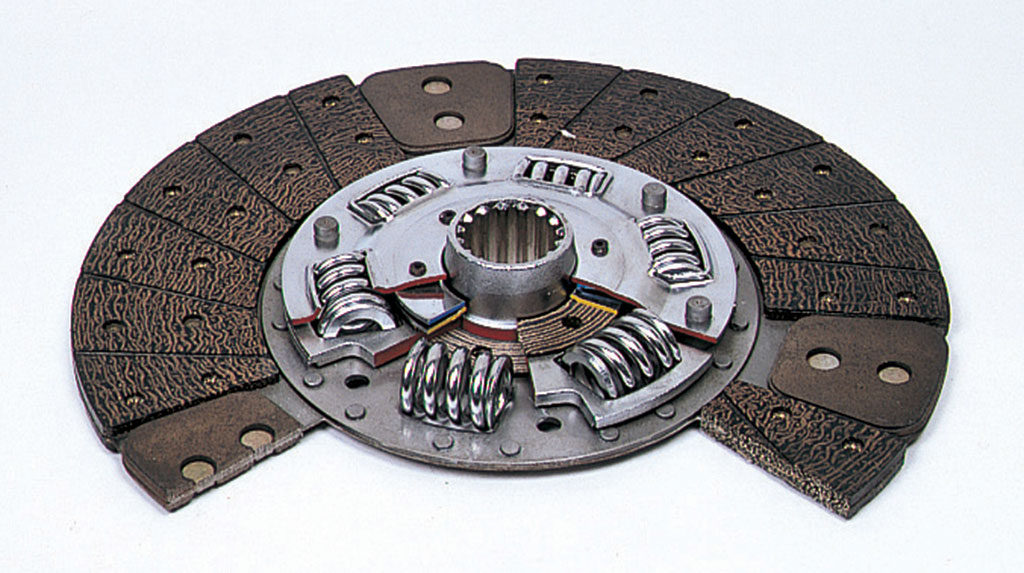

The combustion process creates sudden changes in angular acceleration at the crankshaft.This is why all OEM clutch discs are designed with torsion springs and other components. These are designed to absorb the engine harmonics and vibrations.

Additionally, the clutch disc softens the rotating fluctuations that occur with sharp changes in engine rpm, gear changes and even when shifting into reverse. Evan explained that there are several sets of torsion springs within a clutch disc designed to dampen these frequencies.

There are smaller dampening springs spaced around the splined input shaft assembly on the clutch disk that help prevent chattering noises within the transmission. As the torsion springs do their duty to absorb vibrations through gear shifts, there are several cone springs, friction washers and a friction plate to keep the torsion springs from vibrating themselves.

If you are experiencing excessive vibrations with the clutch engaged (foot off the pedal) or during shifts, it is likely that the clutch disc torsional dampening springs are not matched to your vehicle’s harmonics. This is common when you step up to a performance clutch assembly as the torsion springs will be heavier to accommodate the increase in clamping load from the pressure plate and handle a more aggressive driving style.

The solution for this is to work with the clutch manufacturer to determine if a different clutch disc and pressure plate would be better suited to your engine and transmission combination.

If you’re experiencing more of a chatter or jitter upon engagement of the clutch, the causes can range from misalignment, oil/grease contamination, a warped flywheel or damaged disc.

The first step to solve chatter or jitter is to inspect all of the components for damage. Have the flywheel checked for warp, and resurface or replace it if needed. If oil or grease is present, find the source and fix the leak. If a clutch disc has been covered in oil, it should be replaced. Make sure that all of the components are clean before being installed.

Of course, there are more possible intricacies to diagnosing and solving clutch vibration. We’ve covered the basics in this tech article that cause the common problems that people may experience.

To learn more about the function of a clutch disc and its torsion springs, check out this video from Exedy.