Dual Clutch Transmission (DCT) technology has been around for years. As auto manufacturers strive to further improve fuel economy and powertrain performance, the advantages that a DCT has over a traditional automatic transmission become more desirable. In this article, we’ll explain the differences between a DCT and a traditional automatic transmission.

We’ll start with what is the same: A DCT and a traditional automatic transmission both shift gears automatically. There is no clutch pedal for the driver, and both are actuated by a shifter in which the driver selects Park, Reverse, Drive and some variances of Low or manually selected gears. And that’s where the similarities stop.

How a DCT Works

A DCT actually has more in common with a manual transmission than a traditional automatic. This video shows the key components in a DCT and how power flows through it from the input shaft to the output shaft.

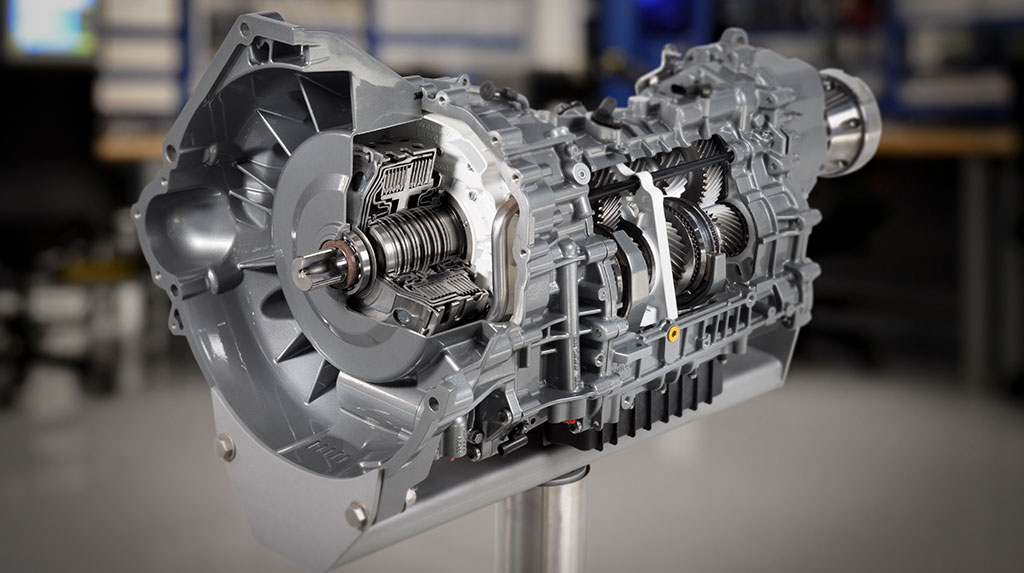

As the “dual clutch” name implies, a Dual Clutch Transmission has two clutch assemblies. It also has two input shafts—one inside the other. The clutches ride on the separate shafts and are used to engage and disengage the shafts individually.

Like a manual transmission, a DCT has synchronizers and shift forks. The difference is that instead of being actuated by a driver via the transmission shifter, the shift forks are moved by an actuation system and controlled by the transmission or powertrain electronic control module (ECM). This is one of the key unique technologies in a DCT, and it is the brain of the transmission.

Typically the odd gears (First, Third, etc.) are on one input shaft, while the even gears are on the other shaft. This allows the transmission to pre-select the next gear and be ready for the next upshift. This is also what makes a DCT capable of extremely quick shifts. Essentially the transmission has already shifted, and changing gears is actually just a matter of disengaging one clutch and engaging the other one.

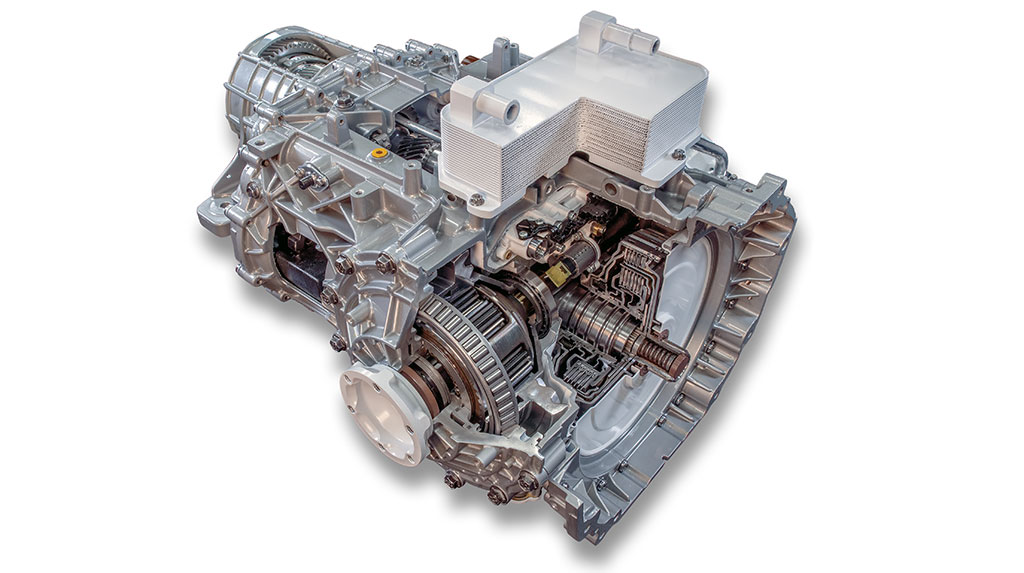

A DCT can be either a traditional longitudinal transmission, used in typical rear-wheel-drive cars, or a transaxle which is also referred to as a transverse transmission. A transaxle combines the function of the transmission and the drive axle, and it has an internal differential to send power to left and right axleshafts. While most transaxles are found in front-wheel-drive vehicles, they are also used in rear- and mid-engine high performance vehicles.

The 2020 Chevrolet Corvette Stingray is an example of a transaxle DCT. It features the TREMEC TR-9080 DCT, our first 8-speed transmission, which includes a nested concentric clutch and integrated differential (either mechanical limited-slip or electronically actuated limited-slip).

An example of a longitudinal DCT can be found in the 2020 Ford Mustang Shelby GT500. The GT500 features the 7-speed TREMEC TR-9070 DCT. This transmission is capable of lightning-quick shifts in as little as 80 milliseconds.

How an Automatic Transmission Works

It’s much more challenging to explain how an automatic transmission works, but here are the basics: An automatic transmission relies on three primary systems to function: planetary gear sets, a torque converter and sets and clutches with a control system. In addition to these systems, there is a gear-driven oil pump to provide hydraulic pressure for actuation.

The torque converter is a fluid coupling. It engages and disengages the transmission from the engine, providing the function of a clutch in a manual transmission. It has two sets of vanes, one attached to the flexplate, which is bolted to the back of the engine crankcase. This set of vanes is called the impeller. The second is attached to the input shaft of the transmission. This set is called the turbine.

When the torque converter spins, oil inside of it is pushed to the outer circumference by the impeller. As the oil pressure around the circumference increases, the oil is pushed onto the vanes of the turbine, beginning to apply rotational force. The faster the engine rotates, the more oil pressure is applied to the turbine, increasing the speed of the turbine until it eventually nearly matches the speed of the impeller.

There are additional components in modern torque converters. You can view the function of the impeller and turbine, in addition to these other components, in this video:

Now, let’s look at the planetary gear set. This is what gives the automatic transmission the various gear ratios to create First gear, Second, Third and so on.

A planetary gear set uses a ring gear, typically three planet gears and a centrally located sun gear. The planet gears rotate between the sun gear and the ring gear. The specific ratio is determined by the diameter of the gears and tooth count. Each primary gear in the transmission is created by adding another planetary gear set. Through the application of clutches, the ring gear can be allowed to rotate, in which case the gear ratio is not applied to the output shaft, or it is held stationary and the gear ratio is applied.

The final set of systems in a traditional automatic transmission are the clutch packs. There are several clutch packs, each one made up of multiple friction discs. These are applied and released through hydraulic pressure and a control system. The clutches hold and release various components, including the input shaft, ring gear and carrier of the planetary gear sets to select the desired gear ratios.

A traditional automatic transmission has considerable slip through the torque converter until the converter is locked, which typically can only happen at a continuous cruising speed. A traditional automatic transmission also has an internal hydraulic pump and a certain amount of engine power is consumed to drive this pump. These two losses of efficiency make DCT more efficient. The DCT also has a performance feel like a manual transmission because of the direct connection of engine power from input shaft to output shaft.

As a leader in manual-transmission technology and manufacturing, TREMEC is proud to have our DCT transmissions used in two of the highest-performing cars produced by American automakers.