Manual Transmission Synchronizers 101

You can thank synchronizers for the quick, smooth transitions that you love when shifting your own gears. These unsung heroes in a manual transmission are critical to shift quality and performance.

We want to give you a better understanding of how they work and some of the key technical advancements in the synchros we use in TREMEC transmissions.

There are several variations in the specific configuration and components used in synchronizers, but this basic function is the same.

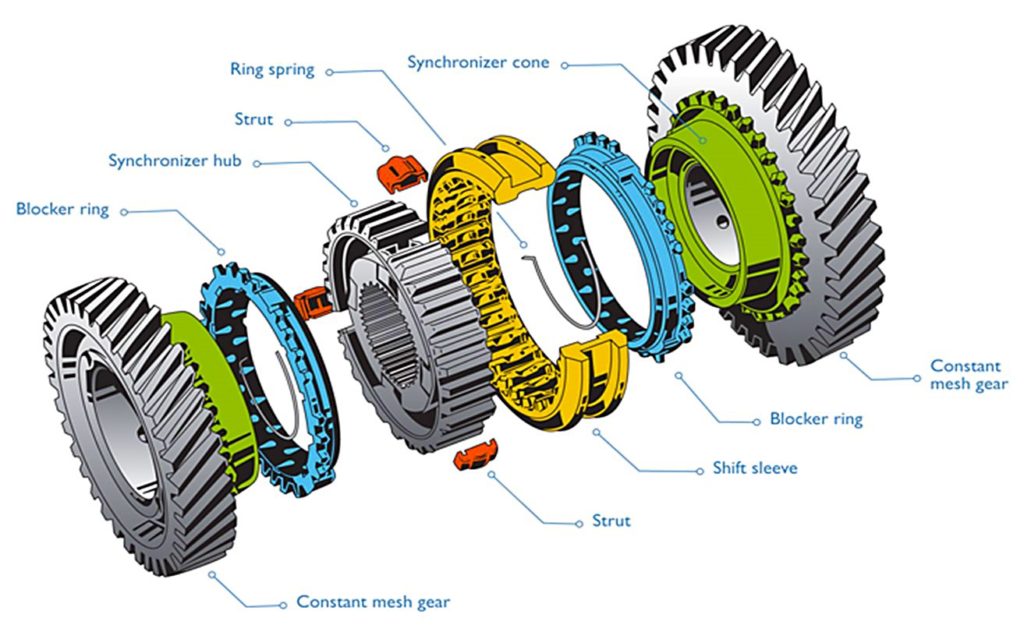

In every synchronizer assembly, there are three primary components:

- Slider, also referred to as a shift sleeve

- Keys, balls or struts, depending on the specific design of the synchronizer

- Blocking rings, also referred to as baulk rings

In most manual transmissions, gears ride on the output shaft and are meshed to gears on the countershaft. To engage a gear, the slider slides over the teeth on one of the gears. This locks the gear to the output shaft and completes power flow through the transmission from the engine to wheels.

The synchronizer adjusts shaft speeds and aligns the gears as you shift so the slider can mesh with the next gear.

There is more than one synchronizer assembly in a manual transmission. The exact number depends on the number of forward gears in the transmission.

Here a more detailed look at the synchronizer operation when you move the shifter to change gears:

- Sliders push against the synchronizer keys, balls or struts, and those push against the blocker ring or baulk ring

- The blocker ring is pushed against the cone on the gear, and friction causes shaft speeds to equalize

- At equal shaft speeds, keys and notches in the blocker ring align

- Slider teeth mesh with teeth along the outside diameter of the blocker ring

- The teeth on the blocker ring act as an alignment ramp, allowing the slider to mesh with teeth on the gear

You can watch how the process works in this animated video.

A further improvement on the standard synchronizer design are multi-cone synchronizers, as used in the TREMEC Magnum 6-speed transmission. The multi-cone design increases the amount of friction surface area the synchronizer can utilize to sync the gear speeds, making for even quicker shifts and raising the rpm range.