The TREMEC engineering team has been hard at work on yet another groundbreaking transmission. The all-new TREMEC TKX is a 5-speed RWD manual transmission with a compact design, increased torque capacity and very smooth shiftability at high engine RPM, making it the ideal addition for resto-mod projects.

There were a number of objectives set forth in the design, including high durability and strength in a universal package. It will fit an extremely wide range of vehicles with few to no floor pan modifications. The result was a compact, end-loaded design as a simple solution to make the transmission compact. And by having an overdrive, both engine wear and fuel consumption are reduced for roadway driving compared to 3-speed and 4-speed transmissions many popular muscle cars and light trucks came with originally.

Better Shifting

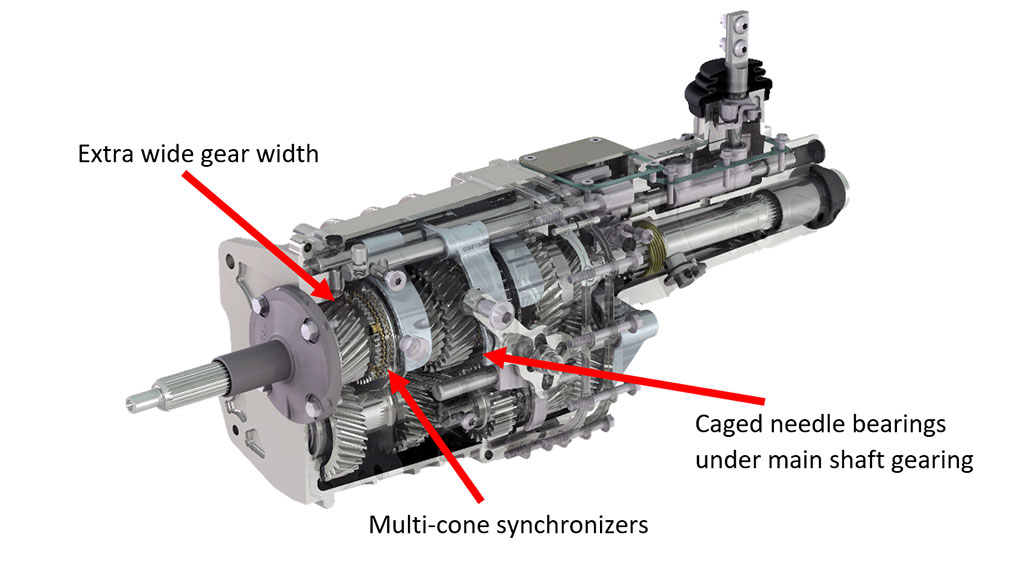

The TKX offers superior shifting performance by way of multi-cone, high-performance, strut-type synchronizers and hybrid (sintered bronze and carbon) synchronizer rings. Having double cones at all gear changes enables power shifting as well as reduced dynamic shift effort. That also ticks the box for no gear clashes at high engine RPMs. An interlock avoids the engagement of two gears. Also, shift travel is 8.75 mm into each gear and an inhibitor system removes the risk of selecting Reverse when the driver is downshifting from 5th to 4th gear. The gears have been case-hardened and shot-peened for strength.

Smoother and Quieter

Another area of note has to do with noise, vibration and harshness (NVH). TREMEC engineers used a ribbed, three-piece aluminum housing – transmission case, intermediate plate and extension housing – for structural stiffness, and this also improved the NVH. This also reduces the potential for leaks. Additionally, there are gaskets at all flanges. Durability continues in the form of oversized gear widths, which can handle high-load shifts, and there are caged needle bearings in all gear positions.

No Gear Sticking

A ball detent is on each shift rail to improve shift feel and provide precise, smooth shifting. Simulation software optimized the size and configuration of the chamfers in the gates and selector finger, so there’s no sticking between gates and shifting stays true in both normal and aggressive driving.

Simple Design

It was important that the TKX be a simple design that would lend itself to easier assembly and disassembly, so that meant having fewer working parts, and also using the cage needle bearings to reduce the risk of missing rollers during service. That all added up to extended bearing life and improvements to lubrication.

High Torque Range

Thanks to many of these technical advancements, the TKX has a rated torque capacity of 600 lb-ft.