A trouble-free conversion to a TREMEC transmission starts with good planning. Selecting the right transmission for your application and knowing the accessories and parts required will prevent headaches during the installation. To give you the best tips to make installing a TREMEC 5-speed or 6-speed transmission as easy as possible, we interviewed some of our TREMEC Elite Distributors about common challenges and mistakes encountered – and how you can avoid them.

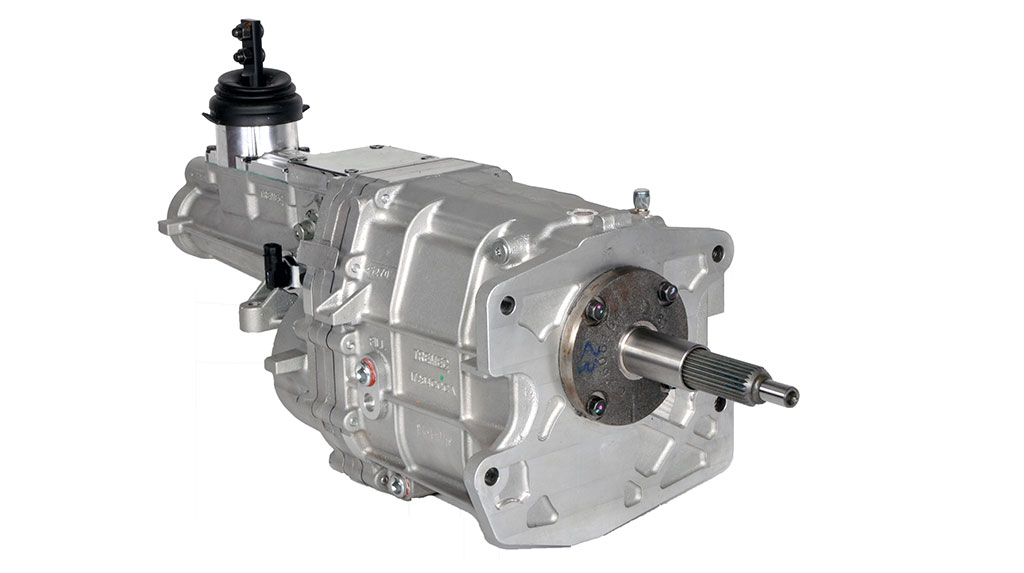

Choose the Best TREMEC Transmission for Your Application

Before deciding on a TREMEC transmission, you first need to understand how the whole package works. The transmission gear ratios, tire diameter, rear axle gearing and how you intend to use your vehicle are major factors to consider. The TREMEC Gear Ratio Calculator is a great tool to ensure that you have the correct axle gear ratio and tire diameter to match the gearing inside the selected TREMEC transmission. This TREMEC blog shows how to use the calculator and understand the data it provides.

Get an Installation Kit if One is Available for Your Car

Next, talk to a TREMEC Elite Distributor about the different conversion kits available for your specific application. These kits can make installation much easier, and many of them provide you with items like a transmission cross member, bellhousing, clutch, shifter and/or transmission tunnel sheetmetal. We’ll talk about several of these items a little later in this article. If you don’t pair all these elements together properly, it can result in more work for you.

After purchasing your TREMEC 5- or 6-speed transmission and accompanying parts, make sure to read the instructions. There are often specific steps, measurements and adjustments to make sure that the installation goes smoothly. And these instructions may explain the process for properly adjustment items such as the clutch and shifter.

Floor and/or Transmission Tunnel Modifications

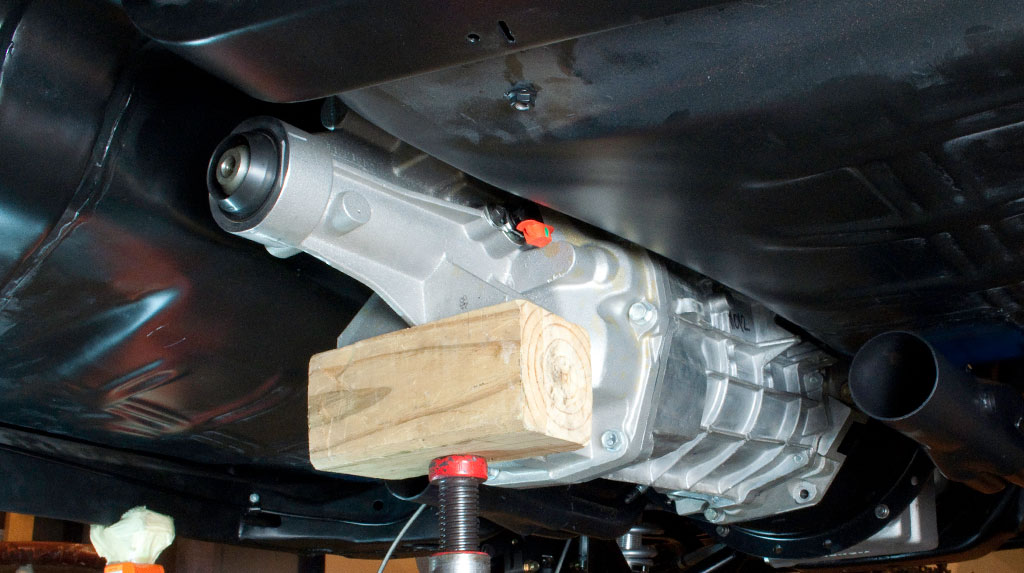

A TREMEC 5- or 6-speed conversion into a classic vehicle may require modifying the floor/transmission tunnel for clearance and proper bellhousing and transmission input shaft alignment.

Most cars from the 1960s and older have relatively narrow and short transmission tunnels. Larger tunnels weren’t necessary to fit the original transmissions (manual or automatic). But they may be inadequate for fitting a modern TREMEC 5- or 6-speed. Modifications to the transmission tunnel may be required, including cutting and welding in extra metal for proper fitment of the TREMEC transmission.

Recently, TREMEC unveiled the new TKX 5-speed transmission, giving a new option to those who don’t want to modify their car’s floor or transmission tunnel. The TKX is shorter and narrower than other 5-speed transmissions, allowing it to fit the transmission tunnels found in most stock muscle cars and other vintage cars. It also has multiple shifter locations, making it adaptable to factory center consoles with little to no modifications.

Some TREMEC Elite Distributors and aftermarket restoration companies offer pre-made transmission tunnel inserts that eliminate much of the measuring and cutting for proper fitment. There are also templates available that show builders where to cut and how much metal to add when a premade insert isn’t available.

“We offer templates and floor patches for those applications where floor mods have to be done,” TREMEC Elite Distributor American Powertrain’s Matt Graves explained. “For most muscle cars, you don’t usually have to cut the floor with our kits.”

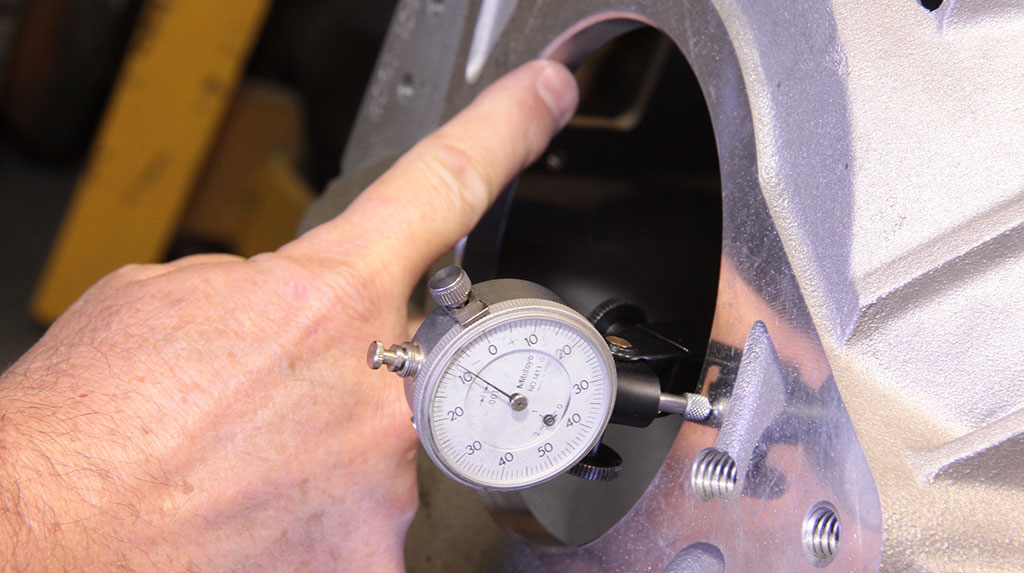

Bellhousing and Input Shaft Alignment

Be sure to check the transmission bellhousing and input shaft for proper alignment. Misalignment of these components and the engine leads to driveline vibration, excessive wear on internal transmission components and hard shifting. In fact, if bellhousing and input shaft alignment aren’t set up correctly, the warranty on your new TREMEC could be voided.

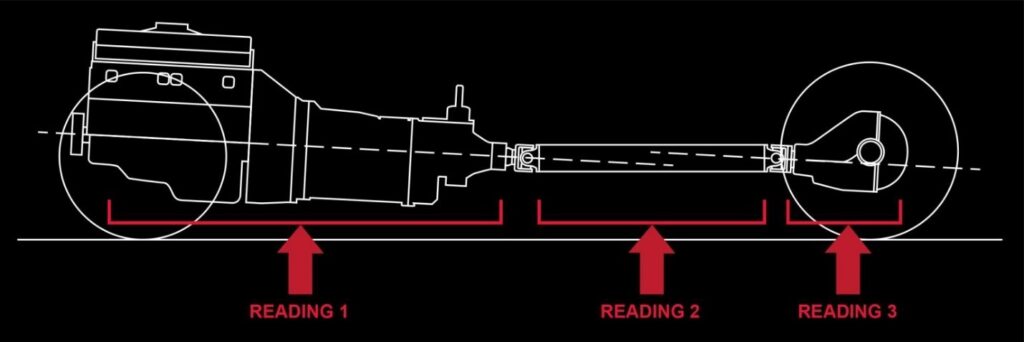

Driveshaft Alignment

Driveshaft angle is another important aspect of a TREMEC installation. Incorrect driveshaft angles cause driveline vibrations that can be felt when driving the vehicle. These vibrations cause abnormal wear on the transmission output shaft, yoke and other internal components and can lead to premature failure. Setting up correct driveshaft angles is easy thanks to the TREMEC Toolbox app and its built-in driveline angle finder. The TREMEC Toolbox app is free for download through the Google Play and Apple store.

Clutch Considerations

Converting an older vehicle with a mechanical clutch to a modern hydraulic system often accompanies upgrading to a TREMEC transmission and with that comes multiple benefits. Effort to actuate the clutch pedal is reduced by at least 15 percent – even more if the old-style, three-finger pressure plate is replaced by a modern, diaphragm-style pressure plate. The conversion also eliminates the clutch linkages that cause interference with long-tube headers and exhaust. You’ll see more consistent, linear clutch pedal travel (where it feels the same through the range of motion) and smoother clutch actuation.

Selecting the correct clutch (disc and pressure plate) for the intended application and use is also key. Chris Ciolek from TREMEC Elite Distributor AMP Performance elaborated, “We work with customers to select the best clutch that will meet their expectation for pedal firmness, but also suit the application and not exceed the torque capacity of the transmission. Is the vehicle going to be just a cruiser for driving around? Will it see street and strip use? Will it mostly be driven on a racetrack? How much horsepower does/will the selected engine make? All these need to be considered when selecting a clutch to go with a TREMEC installation.”

Jeff from Silver Sport Transmissions provided this advice, “Don’t buy too much clutch. Just because your engine makes 500 horsepower doesn’t mean you need a 500 horsepower clutch. Choosing the right clutch requires looking at different factors. If the vehicle is just a street cruiser, a base organic clutch rated for 450 horsepower will be fully adequate. What’s the tire size? A vehicle with 225-width tires will start spinning them well before the clutch might start to slip by being overwhelmed by power.

“Are you planning to hit the track? Track use requires a more aggressive clutch disc friction material to handle the increased power, heat load and traction. What rear end gear and rear tire size are going to be used? If you’re running 3.08 rear gears with a 28-inch-tall tire, it’s almost guaranteed you’ll have clutch chatter. You want to be somewhere close to a 10.0:1 starting line ratio, calculated by multiplying the First gear ratio in the transmission by the rear axle gear ratio. Tire height also affects this calculation and should be kept in mind when changing tire size.”

For vehicles that originally had a mechanical clutch setup, there are different kits available that include everything for a conversion – even a new clutch pedal if you’re converting from an automatic to a manual transmission. If a TREMEC distributor doesn’t have a kit available, they will be able to recommend one from a different source (or an internet search for “hydraulic clutch conversion” for your vehicle year/make/model will give you multiple sources).

Measuring for a New Driveshaft

A driveshaft of a different length (usually shorter than stock) will be required for most installations of a TREMEC installation into a vintage muscle car and other vehicle. Measuring for a new driveshaft isn’t difficult, but it can only be done after the new transmission has been installed. Follow the TREMEC Elite Distributor or driveshaft company’s instructions closely to properly provide measurements to have a new driveshaft built. Generally, you will need a measurement from the rear seal on the transmission to the pinion yoke on the rear axle. This must be measured with the rear suspension sitting at normal ride.

An incorrect driveshaft can lead to driveline vibrations that are annoying and could lead to severe transmission and driveline damage. Read our blog on driveline vibration diagnosis and prevention.

These tips cover the most common mistakes, which are all easy to avoid when installing a TREMEC transmission.