Choosing the correct clutch for your car or truck is crucial for getting the best performance and driving experience with your TREMEC 5- or 6-speed manual transmission. With a clutch not suited for your car or truck’s powertrain and driving conditions, you’ll end up with not just a poor driving experience, but also increased risk of breaking drivetrain components. In race situations increased risk of clutch failure at a crucial moment that could cost you a victory. The wrong clutch means when you try to shift your own gears all you’re going to get is a grinding reverberation though the shifter followed by some choice expletives.

“Customers will often choose a clutch based on the horsepower rating and not factor in the environment the vehicle will be used in,” says Brian Gwin, Sales Director for McLeod Racing “For example, choosing a properly rated clutch for the horsepower they are making, but choosing the ‘street’ version when they intend on driving the vehicle on the street AND taking it to the track.”

When selecting a clutch for your car or truck, there are three factors to consider:

- Horsepower and torque output of your engine

- Driving conditions/environment

- RPM range engine will run at during performance driving

Clutch companies rate their clutch kits for how much horsepower/torque the clutch can handle and not slip while also having a normal clutch life. Using a clutch that’s not rated for the amount of power your engine makes means you’ll end up with clutch slippage when peak power is reached. The clutch slipping means not all the power is going to the transmission and eventually the rear wheels. It also means an increased amount of friction material on the clutch disc will be worn off, leading to premature clutch failure.

Next up, what are you going to be doing/how will you be driving your TREMEC-equipped vehicle? A car or truck that will only be driven on the street with occasional “spirited” driving won’t require the same kind of clutch that a street/strip or dedicated race vehicle requires. On the dragstrip or street with drag racing-style hard launches means the clutch sees more clutch dumps and sudden shocks of power then the more gentle engage a clutch sees on the street. The clutch disc, pressure plate and flywheel all have to be rated for handling the power of such launches plus the heat generated by this kind of driving. For cars seeing autocross or full road course activity it’s the same. But for street-only vehicles if you choose a clutch that’s “too heavy” and meant for harder use and way more power than your engine makes, drivability can be hurt just as much as not having enough clutch. Clutch engagement will be more aggressive and likely bog down the engine possibly to the point of stalling. You’ll also notice more effort needed by your left leg to work the clutch as well.

The last point to consider is what RPM range your engine will be running at during performance driving. If you’re driving in a high RPM environment such as drag or road racing/autocross, you want to select a clutch that can handle the rigors and extra heat generated by that kind of driving. Similar to brakes when they overheat, a clutch that overheats won’t function properly or not at all. And for RPM, with higher RPM applications a different friction material disc will be needed compared to more street-oriented clutch discs.

Dual Disc Clutches

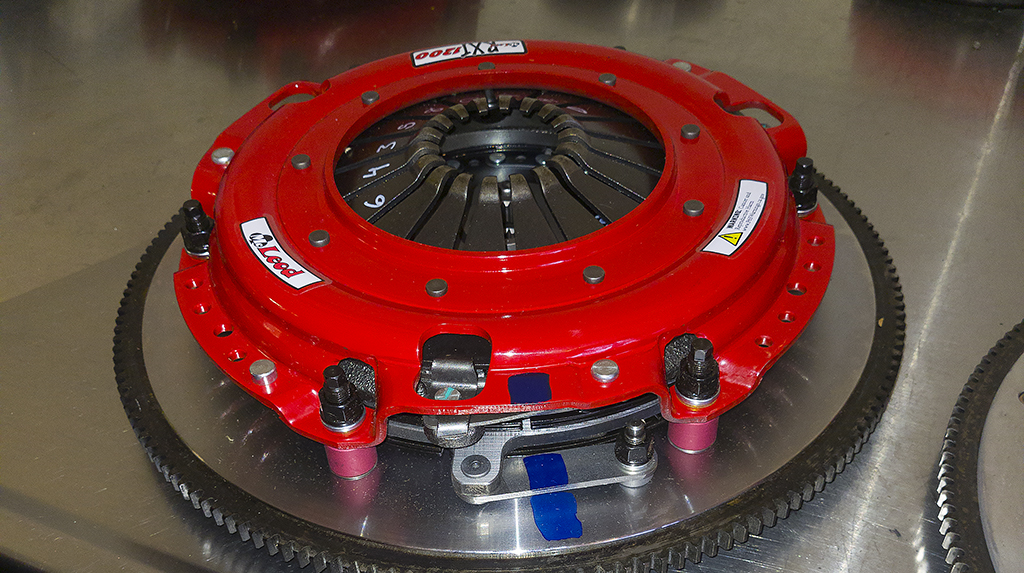

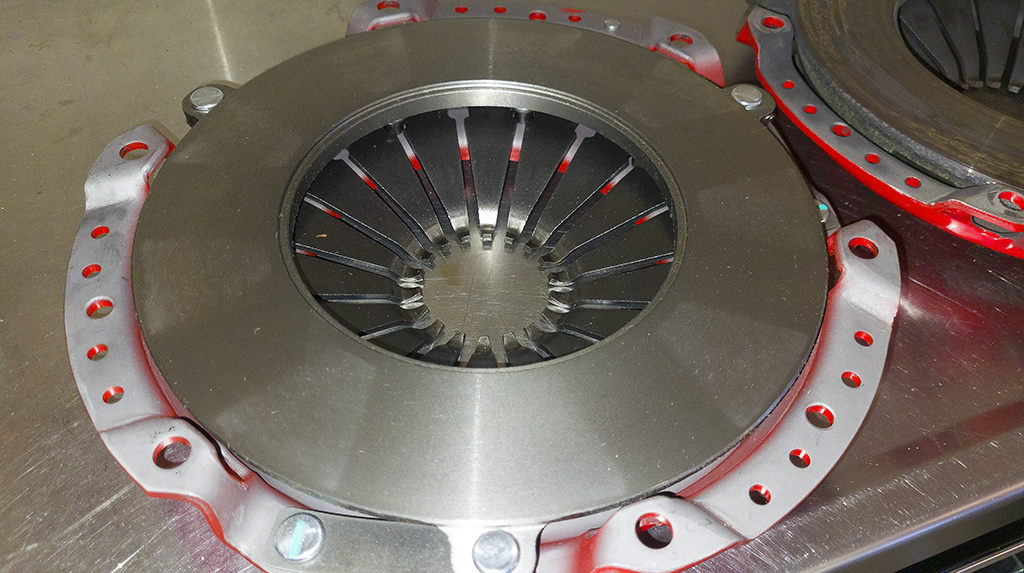

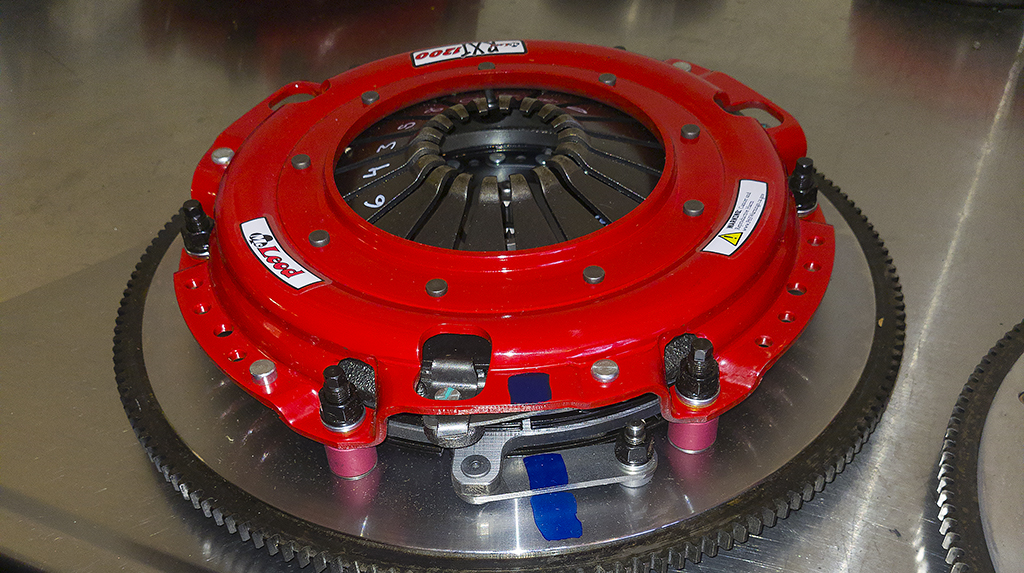

“When the engine is making 600+ hp, there is going to be a high heat load put on the clutch (racing activity), and when the transmission will need to be shifted at high RPM (6500+) it is time to look at going with a dual-disc clutch system” Brian Gwin explains.

Dual-disc clutch systems have come into play more with modern engines and horsepower capability, offering a better option versus a single-disc clutch setup in more applications. A dual-disc clutch usually has a smaller diameter than a traditional single-disc clutch. This helps lower the moment of inertia (MOI) which usually helps reduce pedal effort. Typically they can handle more heat and more power than a single-disc system. Dual-disc systems help for high-horsepower vehicles that see track time but also a fair amount of street time as well but the owner doesn’t want to deal with a heavy amount of pedal effort to work the clutch.

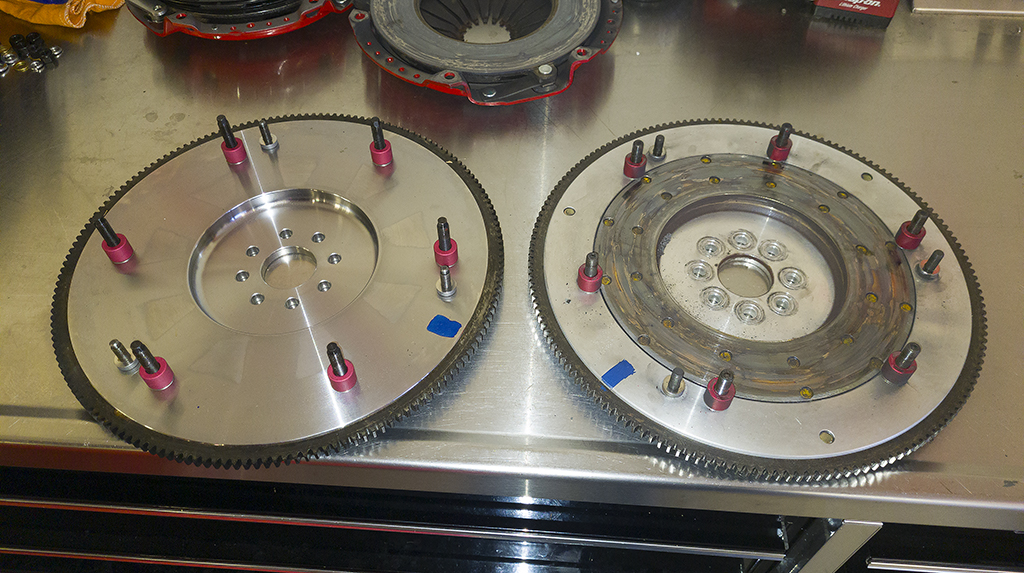

Steel vs Aluminum Flywheel

The main interface between the engine and the clutch is the flywheel. Flywheels are typically made from either steel or aluminum. Aluminum flywheels are much lighter than steel ones for obvious reasons. Most factory manual transmission vehicles have a steel flywheel because that is ideal for most street applications. But when should you look at switching to an aluminum flywheel? For higher performance engines in street/strip vehicles, a billet steel flywheel is the better option where inertia is important and/or the vehicle is a heavy one. Extra inertia in these cases from the heavier flywheel means less tendency for the engine to bog down when the clutch is released and stay in the desired RPM range for launching. Aluminum flywheels and their lighter weight/decreased inertia are ideal for lighter vehicles, road racing, roll racing (drag racing that doesn’t start from a dead stop), circle track racing and any other driving where lighter is better. Aluminum flywheels typically aren’t recommended for cars and trucks primarily driven on the street. If you’re not sure which way to go, ask the clutch manufacturer what they recommend based off your vehicle’s specifications.

When Should You Upgrade Your Clutch?

Composition of the clutch disc friction material is important when talking about race applications, and when it’s time to upgrade from a more street-oriented clutch. When you start using a street disc more in a racing environment, the lifespan of the disc’s friction material will be greatly reduced. On the flip side, the shifting qualities of a street clutch could actually hinder overall performance of a more race-oriented car or truck. Because noise and smoothness aren’t critical factors with a race car compared to a street car, racing oriented clutch discs and pressure plates use friction materials and other parts that prioritize horsepower, heat, dead-stop launches and sharp engagements that overwhelm a street clutch.

What to Avoid When Installing a New Clutch

This one’s easy…FOLLOW THE INSTRUCTIONS! Before picking up a wrench (and even if you’re not installing it yourself) read the instructions included with the new clutch you buy. Besides covering the installation part, they’ll also give instructions on how to drive the car once installation is complete so the clutch is “broken-in” and ready for what you want to do. Clutch companies have an enormous wealth of knowledge, including records of how users screwed up installing a clutch so other customers can be warned not to do the same thing.

Clutch Chatter

Past clutch slippage, the most common issue encountered with clutches is clutch chatter. But what is it exactly? Clutch chatter is when the clutch disc is grabbing and skipping momentarily when taking off from a standstill. Factors that can cause clutch chatter are:

- Contaminated disc or pressure plate

- Transmission not being properly aligned with the engine

- Bent or warped disc, flywheel or pressure plate

- Launching at the wrong RPM

- Mismatched rear end gear ratio and tire size

There can be other reasons for clutch chatter, but these are the most common.

Overall, if you have any questions about which clutch is right for your application, consult with the clutch manufacturer you’re considering. They have experts who are ready and happy to help you figure out which clutch is the right one for your car or truck.