Using an original 1932 Ford coupe body, Matt Snopek built his version of the classic American hot rod with design subtly that keeps you coming back for more looks at this beautiful machine. He only departed from era-correct design and equipment in one area – the 5-window has a TREMEC TKX 5-speed transmission for reliability and driveability.

It all started in 2015, when Matt bought the coupe body, a DeSoto Hemi and a custom built chassis for it from the shop where he was employed. Matt tucked it away while he refined his idea for the build and sought out the necessary parts to make his vision for the 1932 coupe a reality. During these years, Matt started his company, Snopek Kustoms, and found a customer, Vernon Mackillop, who shared in his vision for the 1932 5-window coupe.

“I’ve always been into traditional hot rods and customs,” Matt explains. “I like to build cars with a lot of subtle changes while always keeping proportions in mind.”

As the build concept, which Matt dubbed the Arlo Coupe, was finalized, Matt sold some of the parts he got with the car to help finance purchasing what he wanted to fit the Arlo Coupe’s look. When he acquired the car there was a DeSoto Hemi with the assortment of parts, but using it in the coupe was never an option for Matt. Only one engine would be right for the build: a classic Ford flathead V8.

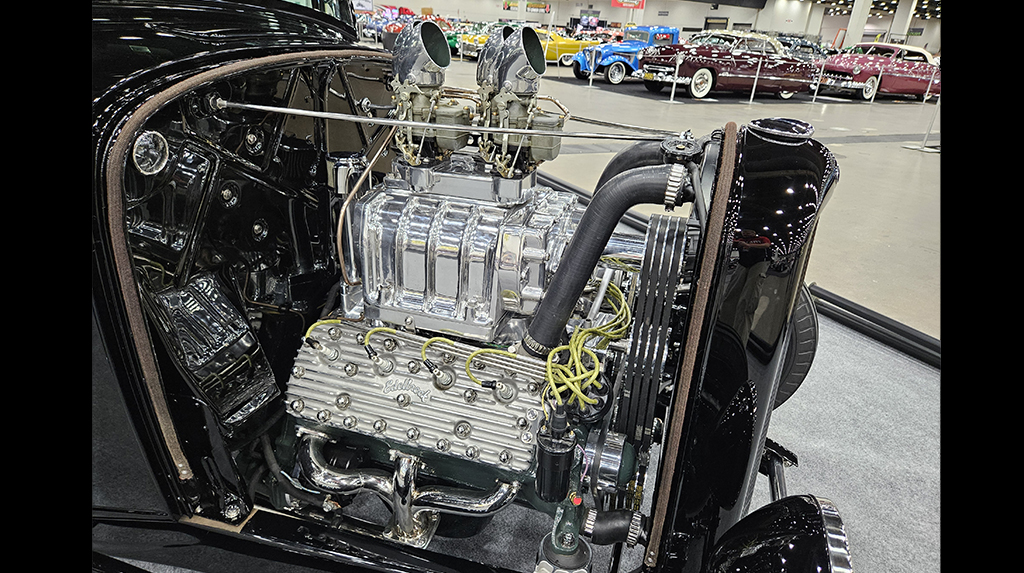

Uncommon Engineering was tasked with making the front accessory drive that would connect everything while retaining the desired look. They also built a wooden mold to cast a custom aluminum intake for mounting the supercharger to force feed the flathead and help make decent power. The fuel is delivered by a pair of vintage Stromberg carbs that Matt built the linkage setup for. Bolted to the flathead is a TREMEC TKS 5-speed transmission built by Liberty’s Gears with Quick Slip coated gears. It sends power to a Ford 9-inch rear.

The body of the 1932 Ford Arlo Coupe is all steel and mostly original sheetmetal. True to his craft and building classic builds, Matt works with lead on areas that need work more than a quarter-inch thick. To keep the proportions just right, the front end was shortened and the top chopped just enough to have everything in balance. Then the steel was prepped and primed for being sprayed in PPG Deltron urethane black. Inside Fat Lucky’s Interiors in Arizona did the interior stitching, using material from an out-of-business custom suit tailor that made zoot suits to give the interior some extra depth and detail, as well as the gangster look that the owner of the car desired.

“A lot of work from very talented people helped me complete this build and fulfill vision for it. I love seeing people check out the carbs, and watching their eyes keep moving from one aspect of the coupe to the next.”