Swapping a TREMEC TKX 5-speed transmission in place of an original Ford Toploader 4-speed is an easy process that transforms the way a classic car drives and feels. For this article, we photographed the transmission upgrade on a 1966 Mustang, which is a great example of how the compact TKX was designed for easy fitment in early Pony cars and muscle cars. The Ford Toploader was one of the best factory 4-speeds you could get during the muscle car era. But it is easy to see how the overdrive, increased torque capacity and improved shift feel in the modern TREMEC TKX 5-speed is a great upgrade.

The TREMEC TKX was designed with classic cars in mind. Its case was designed specifically to allow for installation in older vehicles with narrow transmission tunnels without having to cut/modify those tunnels for fitment. With the TKX multiple shifter locations, in most cases owners can locate the shifter to reuse factory center consoles without major modifications. Functionally the TKX allows for 7,500 engine-rpm shifts thanks to synchronizer technology shared with the TREMEC Magnum 6-speed family. This also gives the TKX a smooth and easy shifting feel.

When it comes to torque handling capacity, the TKX easily bests the old Toploader with a 600 lb-ft torque rating. Combined with its large, fine-spline input shaft and helical gear design, the TKX can handle street/strip and full-on race duty behind vintage and modern engines while still giving you a great driving experience on the street.

The TKX is available with optional gear sets for First through Third gears and three different Overdrive gear ratios. If you’re not sure which will match up with your current or planned rear end gear ratio, the TREMEC Gear Ratio Calculator can help you determine speed and engine rpm in each gear with any rear-axle gear ratio to help choose which is best for your car or truck.

Here is a comparison in gearing between the TKX and wide-ratio Ford Toploader:

| TKX | 1966 Ford Pass Car Wide-Ratio Toploader | |

| First | 3.27/2.87 | 2.78 |

| Second | 1.98/1.89 | 1.93 |

| Third | 1.34/1.28 | 1.36 |

| Fourth | 1.00 | 1.00 |

| Fifth | .68/.72/.81 | N/A |

| Reverse | 3.00/2.56 | 2.78 |

The swap subject in this article is a restomodded 1966 Ford Mustang that has a built Ford 302 with a turbocharger setup. The owner loved driving the car locally, but even at minimal highway speeds, the small-block would be screaming due to no Overdrive and the low rearend gears it has. He was ready to upgrade and went to KM Performance and Fabrication to get his Ford Toploader replaced with a new TREMEC TKX 5-speed transmission. The TKX came from Dederichs Motorsports, a TREMEC Elite Distributor that offers complete TREMEC kits including transmission and accessories necessary for installation into a variety of classic and late model vehicles. Dederichs also offers mechanical to hydraulic clutch conversion systems and even clutch pedal setups for converting from automatic to manual transmission.

Details of the swap are outlined in the photos and captions.

The old Ford Toploader 4-speed transmission is great for an original restoration car that needs to be factory correct. But for today’s driving and highway speeds, a TREMEC TKX 5-speed transmission will make the driving experience so much better. The subject for this swap is a 1966 Ford Mustang with a wide-ratio Toploader that was fine driving at in-town speeds but had the engine spinning at uncomfortably high engine rpm on the highway.

Removal of the original transmission included removing the driveshaft – don’t forget to to plug the output shaft to avoid losing a ton of fluid – and the factory shifter linkage. This is an area where modern 5- and 6-speeds are superior to vintage 4-speeds. The old shifter linkages would often bind or jam when shifted aggressively. The TKX and its internal shiftrails mean no hangups even when shifted hard in race situations.

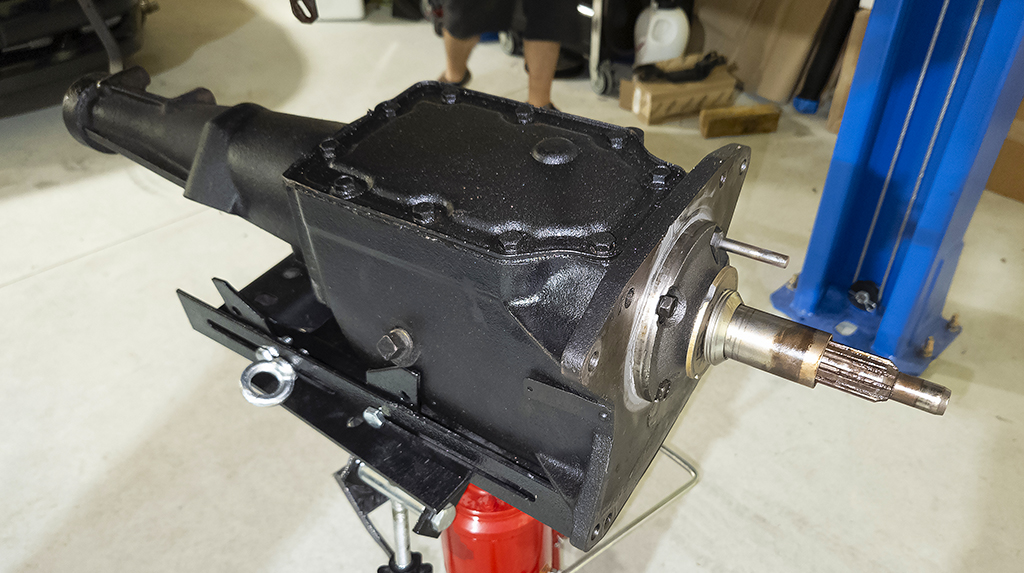

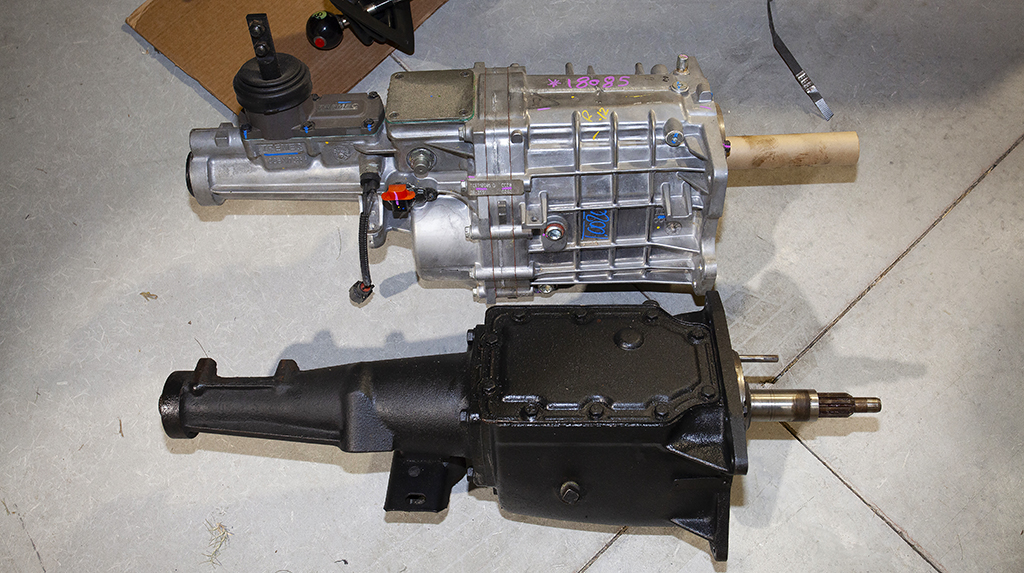

The Toploader featured a cast iron case. We weighed the Toploader and the TKX to see what the weight difference was. Dry and without bellhousing for either, both transmissions weighed about 99 pounds. That’s impressive considering that the TKS is a longer case with five forward gears including overdrive.

Here’s the side-by-side comparison of TKX (top) and Toploader (bottom). You can see that the overall length and width differences are minimal, making fitment into the stock transmission tunnel possible. The TKX actually opens up some space in the tunnel with the elimination of the external shift linkages of the Toploader. The TKX features multiple shifter location options so it’s bench seat and factory center console friendly.

This 1966 Mustang already had a hydraulic clutch conversion installed, so most of it was reused. One important thing if you have a similar situation is this shim for the hydraulic throwout bearing. This must be reused or you’ll end up with a clutch that doesn’t work correctly.

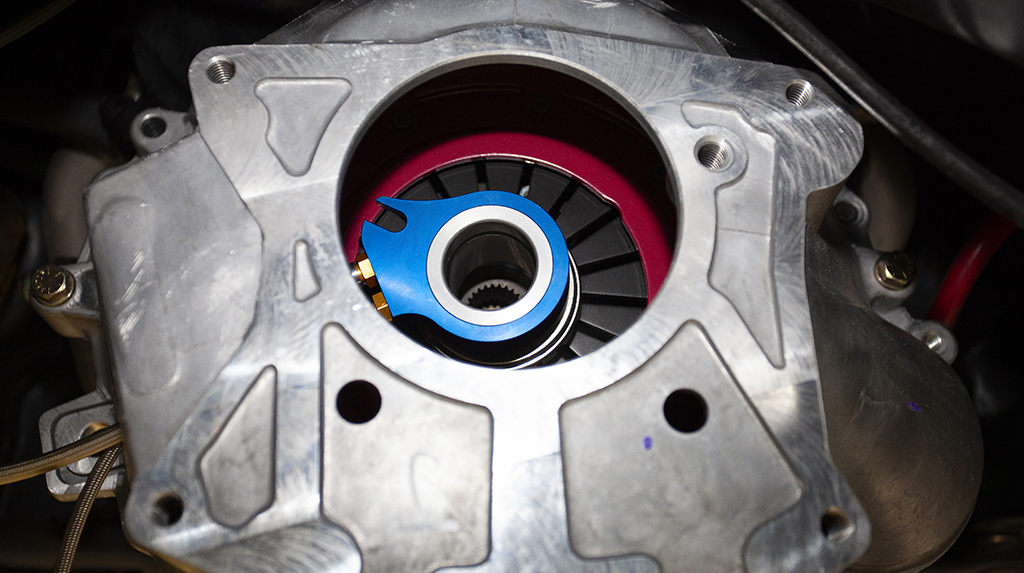

The throwout bearing used with the Toploader was too small diameter to fit on the TKX, so a replacement that fits the TKX was ordered from American Powertrain. They have a full line of clutch conversion systems along with complete transmission swap kits and shifters as well.

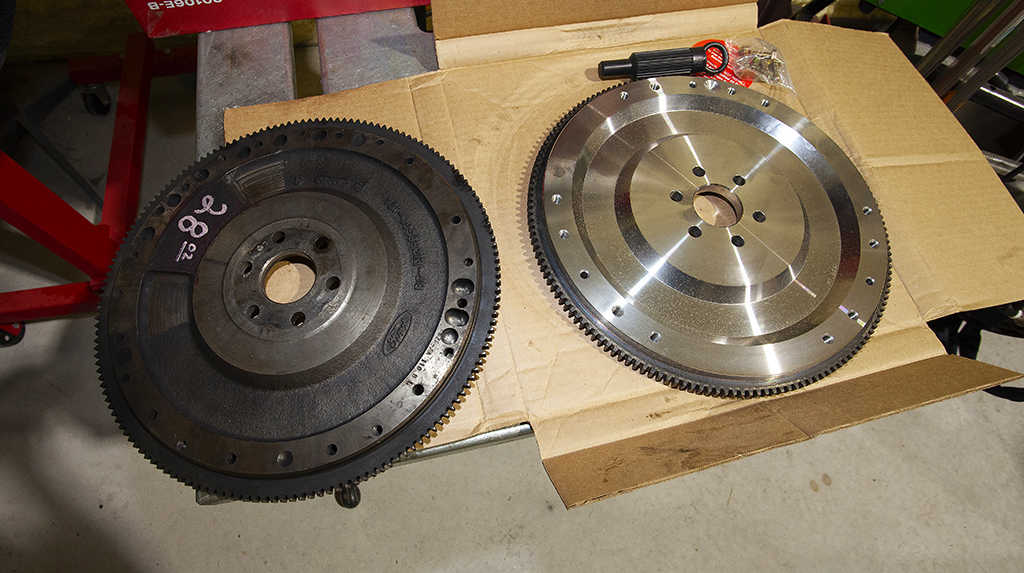

Part of the swap included a new flywheel rated for what the TKX could let the engine do now, with the proper weight and balancing for the Mustang’s 302. A new pilot bearing matching the TKX input shaft was also installed. The pilot bearing is a small part that’s often overlooked, but the bearing (or bushing) is worn or incorrect, it can cause major problems such as make transmission installation not possible or allow movement of the input shaft once installed, which will damage the transmission.

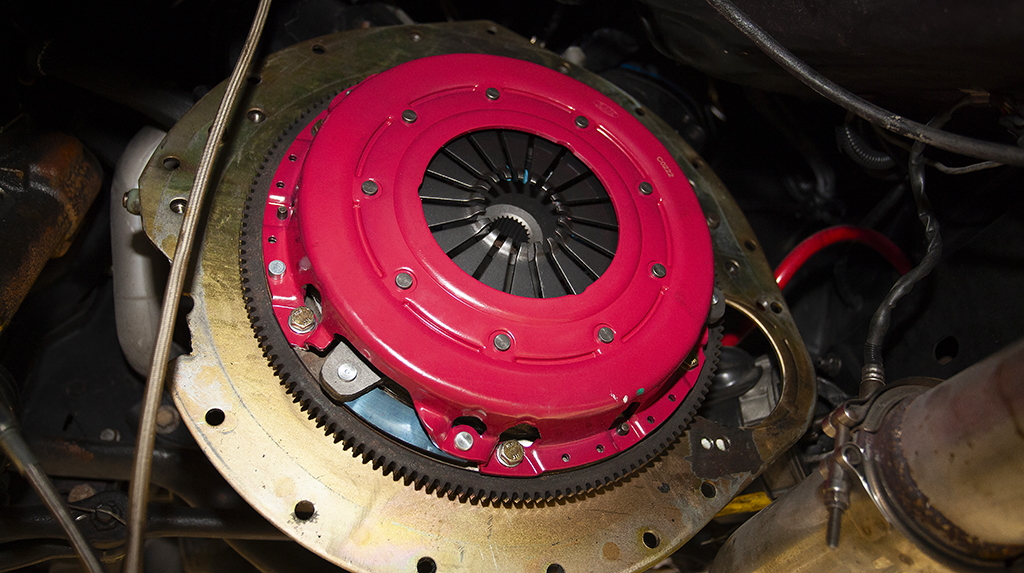

With the TKX expanding what the Mustang could do with all that turbocharged horsepower, a more aggressive clutch was needed. A new McLeod Racing single-disc clutch system was installed with a more aggressive disc friction material than the previous clutch. The mid-plate the Mustang already had was reused, but this isn’t always the case. The TREMEC Elite Distributor you get your TKX (or Magnum) from can help you figure out which plate you’ll need.

The old and heavy steel bellhousing the Toploader used was set aside for the swap meet, and a new a factory-style aluminum bellhousing was used. The new American Powertrain hydraulic clutch throwout bearing was also put in place and line up for the TKX. With this throwout bearing, one bolt on the transmission input shaft is replaced with an alignment stud.

The last step was bolting the TKX in place. The new transmission crossmember was omitted for photo reasons. You can see how the TKX fits the tunnel perfectly. The car’s existing driveshaft was reused by changing the slip joint to match the TKX output spline count. Always check the length of the slip joint and cycle the suspension to ensure that there is sufficient engagement but it doesn’t bottom out either. Now this 1966 Mustang can meet its full performance potential as well as be driven on the highway with pleasure.